Hilleberg Technical Product Information

Why Buy a Hilleberg?

- Superior fabrics for strength, reliability, and low weight

- The linked inner and outer tents allow for easy and quick pitching.

- The inner and outer tents can be used separately. Use the inner tent alone in warm and dry conditions.

- Roomy vestibules provide both gear storage, and protection for the inner tent door.

- The GT vestibules add even more space.

- Unmatched weight to space and strength to weight ratios

- Original and innovative designs for the greatest versatility

- Tremendous durability for years of use

Hilleberg Performance Principals:

Reliability:You must be able to depend on your Hilleberg tent. All materials, design elements and construction techniques - outer tent fabrics, pole diameter and guy line placement - must be able to exceed the performance parameters in each label category.

Adaptability:

A Hilleberg tent must perform equally well across the entire spectrum of its Label category performance range.

Ease of use:

Every Hilleberg tent features linked inner and outer tents for easy and quick pitching, even in bad weather. For Black & Red Label models that means being able to pitch the tents easily even in high winds and blowing snow, and in the dark.

Durability:

Given its performance range of use, your tent must be able to withstand the daily weather conditions of your trips, but it must also last as long as possible.

Comfort:

Comfort in the backcountry is not about “luxury”, but it is basic “liveability”. That’s why all Hilleberg tents are built with bright, spacious interiors and venting solutions that keep air flowing in all weather conditions.

Low weight:

Making a reliable, adaptable and easy-to-pitch tent that is heavy doesn’t meet Hilleberg standards. Hilleberg’s ultimate aim is not to make the lightest tents, but, within each tents performance range, the lightest, strongest, most reliable, dependable, comfortable and durable ones. They have an option of tents made with different weight Kerlon fabric, ranging from Kerlon 1800 / Kerlon 1200 / Kerlon 1000 / Kerlon SP.

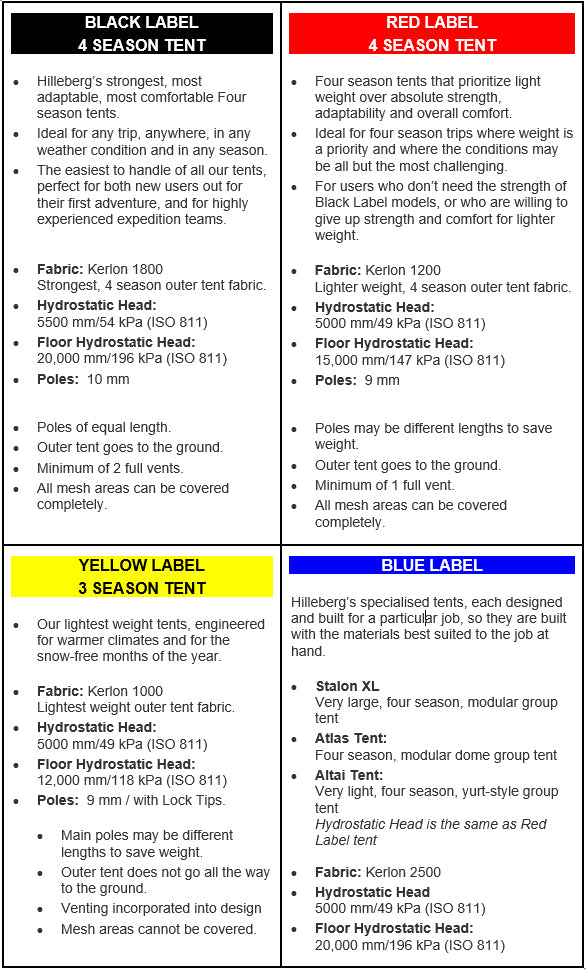

Choosing the right tent with the Hilleberg Label System

The Hilleberg label system divides all tents into one of four categories, or “Labels” - Black, Red, Yellow, or Blue, each label representing a performance range based on materials, construction or both. This grouping makes it straightforward to see the differences within the tent ranges, and makes selecting the right Hilleberg tent for you much easier.

There really is no “best” tent, but there is a “right” tent for you. Choosing that “right tent” is less about what you do on your adventures - climbing, hiking, hunting, sea kayaking, bicycle or motorcycle touring and so on - than it is about determining what your tent needs to be able to do on those adventures.

We believe that you should establish when, where, and how you will most often use your tent as well as any specific features or performance attributes that are important to you, and that you assess your general level of experience and confidence in your backcountry skills. With this information, you can then determine the tent (or tents) with the most suitable qualities for your needs.

In general, the more demanding the terrain and/or the weather you are likely to encounter, the more advisable it is to have a more robust tent.

Tent Materials: Uncompromising Quality

Strength. reliability, low weight and durability. These are the qualities we demand from all the materials that we use in making a Hilleberg tent, and we have rigorous standards that every material must meet.

We are also constantly testing that performance, from the strength and durability of our fabrics and poles to the reliability of our zippers, guy lines, line runners and fittings. We use lab tests and field tests, and we are always seeking better material solutions.

FABRICS:

A tent’s fabrics are what protect you from the elements. In a Hilleberg tent, those fabrics must perform to challenging criteria in a number of areas, which we check in the lab, with standardised tests, as well as in the field - A Hilleberg Kerlon outer tent fabrics must meet a specific tear strength (see “The Importance of Tear Strength”), as well as a minimum waterproofness rating, or “hydrostatic head,” and a minimum colour resistance to light.

While the outer tent’s fabric keeps the elements out, the inner tent fabrics must serve to keep the occupants as comfortable as possible. Hilleberg inner tent fabrics are very lightweight and both air permeable and highly breathable, so they let moisture vapour escape while keeping actual water drops from penetrating

Also vital to the tent’s performance are its floor fabrics. Hilleberg’s tent floors are not only extremely waterproof, but are also highly puncture and abrasion resistant, and will stay flexible even in the coldest temperatures.

POLES:

A high performance tent must have a skeleton worthy of the strength of its skin. We use DAC poles, because we believe they offer the kind of superior performance that the tent fabrics do, and on most tent models, we use the DAC Featherlite NSL poles. The section-connecting inserts on the NSL poles are nearly the same diameter as the pole section itself, so the poles are both significantly stronger and lighter than standard-style poles.

Hilleberg select the optimal pole length(s) and diameter for each tent model, and if necessary they pre-bend them. 9 mm poles go into both the Yellow Label and our Red Label models because, like these models’ Kerlon 1000 and 1200 outer tent fabrics, they offer plenty of strength at a very low weight. Hilleberg use stronger 10 mm poles with their Black Label tents, since these are designed to handle the most extreme conditions.

OTHER TENT MATERIALS:

Hilleberg choose and evaluate the other materials on their tents – zippers, guy lines, pegs, and other fittings – with the same rigor we apply to fabrics and poles. They use YKK zippers, which they have found are the strongest and most reliable available.

The proprietary guy lines are a blend of super strong Vectran fibers and polyester, uniquely interwoven so there is no sheath to separate from the core. They are very light and strong, absorb almost no water, and have negligible stretch.

All Hilleberg tents come with the appropriate aluminium pegs, extra robust yet quite light pegs with the Black Label tents, very light and strong pegs with the Red Label tents, and super light but still quite strong pegs with Yellow Label models.

Smaller fittings are equally well-considered. The simple polymer line runners will hold tenaciously even on wet or frozen cord, and yet can be easily adjusted. The polymer pole clips, pole tensioner cups, the metal ladder lock buckles on pole and peg tensioners (we use metal because these buckles must be as strong as possible) and the adjustable peg loops are all immune to wet and cold, and can be operated easily, even while wearing bulky mittens.

The Importance of Tear Strength

GREATER STRENGTH EQUALS GREATER SAFETY

The stronger the fabric on your outer tent is, the less likely it is to tear because of bad weather, rough handling, or accidental mistakes.

Hilleberg Kerlon outer tent fabrics are very strong:

- Kerlon 1800: Used in Hilleberg Black Label tents

- Kerlon 2500: used in some of Hilleberg’s Blue Label tents and in their tarps,

- Have a minimum tear strength of 18 kg/40 lbs and 25 kg/55 pounds, respectively.

- Kerlon 1200: Used in Hilleberg Red Label tents

- Has a minimum tear strength of 12 kg/26.5 lbs.

- Kerlon 1000: Used in Hilleberg Yellow Label tents

- Has remarkable 8 kg/17.5 lbs minimum tear strength.

- Even better, this strength comes in impressively low weight packages. In real life usage in the field, the combination of strength and light weight translates into tents that in our opinion outperform those made with other fabrics.

The Silicone Connection

Not all silicone-coated fabrics are created equal, however Hilleberg Kerlon fabrics are coated on both sides with a total of three layers of 100 percent silicone. They are completely waterproof and very light, but our process also imparts strength to the base material that is an order of magnitude greater than is possible with the more common polyurethane coating process.

Perhaps more importantly, Hilleberg coated Kerlon fabrics are also far stronger than so-called “siliconized” materials, which typically employ a coating mixture of silicone and other compounds.

This means that we can start with lighter weight base fabrics and still produce outer tent materials that are stronger overall, and in the case of Kerlon 1800, 1200 and 2500, that are stronger than many of the so-called “expedition grade,” heavy duty tent materials on the market. It also means that if your outer tent does suffer a puncture, our high tear strengths make it far less likely that the puncture will develop into a trip-ending hole.

Such high tear strength is like insurance: It is much better to have it and not need it than to need it and not have it, especially since this “insurance” adds no extra weight, and increases the durability and longevity of your tent as well.